Hey there! As a supplier of pure iron, I often get asked about the crystal structure of pure iron. It's a super interesting topic, and I'm excited to share what I know with you.

Let's start with the basics. Pure iron is an element with the atomic number 26, and it's symbolized as Fe on the periodic table. In its pure form, iron can exist in different crystal structures depending on the temperature and pressure conditions. There are mainly three types of crystal structures for pure iron: alpha-iron (α-Fe), gamma-iron (γ-Fe), and delta-iron (δ-Fe).

Alpha - Iron (α - Fe)

Alpha-iron is the stable form of pure iron at room temperature and low temperatures. It has a body - centered cubic (BCC) crystal structure. Picture a cube where there's an iron atom at each of the eight corners of the cube and one more atom right in the center of the cube. This BCC structure gives alpha-iron some unique properties.

One of the key features of the BCC structure is that it has relatively large interstitial spaces between the iron atoms. These spaces can accommodate small impurity atoms like carbon. However, the solubility of carbon in alpha-iron is quite limited, only about 0.022% at 727°C. This limited solubility plays a crucial role in the heat - treatment processes of steels, which are alloys of iron and carbon.

The BCC structure also gives alpha-iron good ductility and toughness. It can deform easily under stress because the atoms can slide past each other along certain crystallographic planes. This makes alpha-iron suitable for applications where forming and shaping are required, such as in the manufacturing of wires and sheets.

Gamma - Iron (γ - Fe)

As the temperature of pure iron rises above 912°C, it undergoes a phase transformation from alpha-iron to gamma-iron. Gamma-iron has a face - centered cubic (FCC) crystal structure. In an FCC structure, there are iron atoms at each of the eight corners of the cube and one atom at the center of each of the six faces of the cube.

The FCC structure of gamma-iron has a different atomic arrangement compared to the BCC structure of alpha-iron. The interstitial spaces in the FCC structure are smaller, but the overall packing of atoms is more efficient. This results in a higher density for gamma-iron compared to alpha-iron.

Another important aspect is the solubility of carbon in gamma-iron. The FCC structure can dissolve a much larger amount of carbon, up to about 2.11% at 1148°C. This high carbon solubility is the reason why austenite, which is the name for the solid solution of carbon in gamma-iron, is a key phase in the heat - treatment of steels. By controlling the amount of carbon dissolved in austenite and then cooling it at different rates, we can achieve a wide range of mechanical properties in steels.

Delta - Iron (δ - Fe)

When the temperature of pure iron goes above 1394°C, it transforms into delta-iron. Delta-iron has a body - centered cubic (BCC) structure, just like alpha-iron. The reason for this phase transformation back to the BCC structure at high temperatures is related to the thermal energy of the atoms. At very high temperatures, the BCC structure becomes more stable again due to the increased atomic vibrations.

The properties of delta-iron are similar to those of alpha-iron in terms of the crystal structure. However, because of the high temperature at which it exists, it's not commonly used in its pure form in industrial applications. Instead, it plays a role in the melting and solidification processes of iron and steel.

Now, let's talk about how these crystal structures relate to the products we offer as a pure iron supplier. We have a variety of high - quality pure iron products, such as DT4 High Purity Iron Rod Hot Rolled Customized Ultra Low Carbon. These rods are made from pure iron, and the crystal structure of the iron affects their properties. For example, if the rods are processed at a temperature where alpha-iron is the stable phase, they'll have the ductility and toughness associated with the BCC structure.

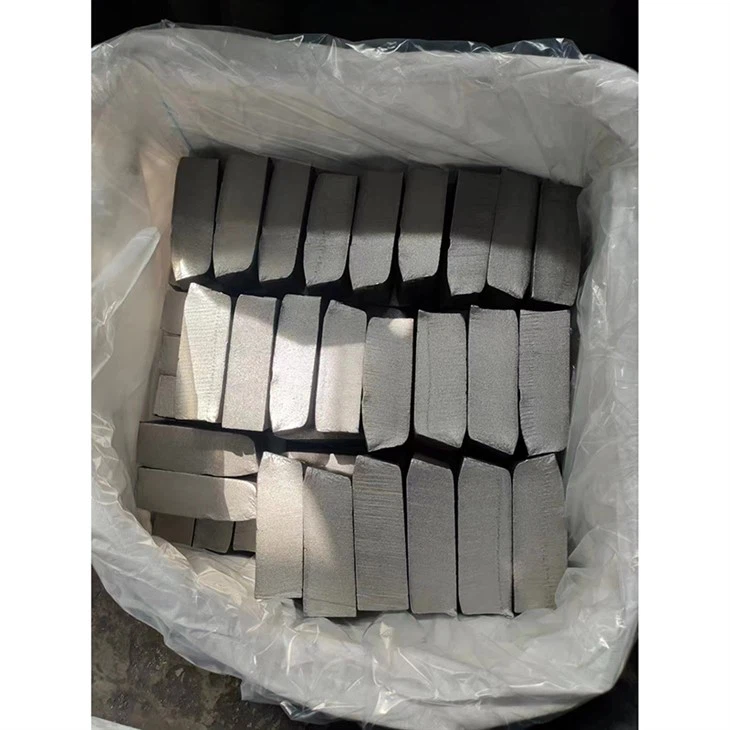

Our Pure Iron Billet For Secondary Smelting is also influenced by the crystal structure of pure iron. During the secondary smelting process, the phase transformations between alpha, gamma, and delta iron can occur depending on the temperature. Understanding these phase transformations is crucial for controlling the quality and properties of the final product.

And our Foundry - Grade Pure Iron is used in foundry applications. The crystal structure of the pure iron affects how it flows and solidifies in the mold. For instance, the different densities of alpha, gamma, and delta iron can lead to volume changes during solidification, which need to be taken into account to avoid casting defects.

If you're in the market for high - quality pure iron products, whether it's for research, manufacturing, or any other application, we're here to help. The crystal structure of pure iron is a fascinating topic that has a direct impact on the performance of our products. We can provide you with the right pure iron products based on your specific requirements.

If you're interested in learning more about our pure iron products or have any questions about the crystal structure of pure iron and how it relates to your needs, feel free to reach out. We'd be more than happy to have a chat and discuss potential business opportunities.

References

- Callister, W. D., & Rethwisch, D. G. (2011). Materials Science and Engineering: An Introduction. Wiley.

- ASM Handbook Committee. (1990). ASM Handbook Volume 1: Properties and Selection: Irons, Steels, and High - Performance Alloys. ASM International.